What Is a Programmable Logic Controller (PLC)?

A Programmable Logic Controller (PLC) is a computer designed specifically to control

machines and processes in factories. PLCs are built to withstand harsh industrial

environments, featuring robust designs that are resistant to dust, moisture, and high

temperatures. By monitoring inputs and managing outputs, PLCs simplify complex

control tasks—from overseeing production lines to managing intricate operations in real

time.

Types of PLCs: Fixed and Modular

In general, there are two types of PLCs, each suitable for different applications:

- Fixed PLCs

These compact units have a predetermined number of inputs and outputs, making

them a budget-friendly option for smaller, standalone applications. However, expandability is

limited, which means they’re best suited for specific, unchanging control tasks. Fixed PLCs are

more complicated to change or fix, and if a defect occurs, it may be necessary to have a backup

unit in order to avoid excessive downtime.

- Modular PLCs

These offer more options as one can customize them by adding or removing

modules and thus they are suitable for large or changing industries. Though they tend to be

expensive and bulky, modular PLCs prevent prolonged system downtime since a given module

serves a specific function and so faults can be located without switching off the whole system.

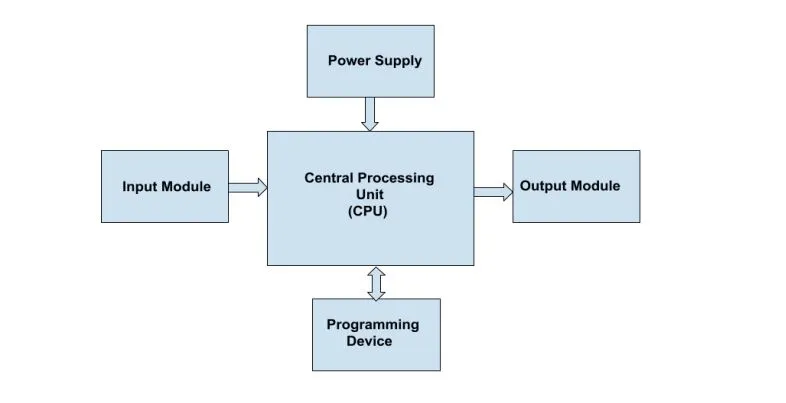

What are the Key Components of a PLC System?

- Input Modules

Receive signals from sensors, devices such as switches and

buttons and change them into a format recognizable and manageable by the

PLC.

- Central Processing Unit (CPU)

Also referred to as the “brain” of the PLC, the

CPU interprets input signals and executes programmed instructions to control

outputs.

- Output Modules

These modules manage output devices like motors, lights, and

actuators.

- Power Supply

Provides the required operating power for the PLC and its

components.

- Programming Device

A device, usually a computer, used to program the PLC.

How PLCs Work?

The operation of a Programmable Logic Controller comprises three steps that run recurrently for

the purpose of providing control in real time.

- Input Scanning

The PLC scans and reads signals from any input device

connected such as sensors, momentary switches and other switches.

- Program Execution

The program downloaded into the PLC evaluates the input

data and determines the corresponding output actions.

- Output Activation

The PLC sends signals to the output devices, such as

motors, lights, and actuators, to perform the tasks it has been programmed to do.

This sequence occurs repeatedly at a higher rate so as to ensure that the PLC is able to

react quickly to varying input conditions. Inputs and outputs (I/O) can be either Digital

(on/off) or Analog (range of values, like a dimmer switch), which increases the scope of

operations that a PLC can perform.

What are the Common PLC Programming Languages?

PLCs are programmed using languages designed for efficiency and ease of use in industrial

applications. Commonly used PLC languages are:

- Ladder Logic

Resembles relay logic diagrams and is user-friendly for

technicians.

- Function Block Diagrams (FBD)

Uses blocks to represent functions and their

inputs/outputs.

- Structured Text (ST)

High-level, text-based language suitable for complex

processes.

What are the Advantages of PLCs?

PLCs have become essential in industrial automation due to several significant advantages:

- Reliability

The solid-state design makes them less prone to failures, making

them more durable than mechanical relay systems.

- Scalability and Flexibility

Modular PLCs can be expanded or modified to

accommodate changing requirements and demands.

- Speed

PLCs process inputs and outputs quickly, providing real-time control of

processes.

- Cost-Effectiveness

While initial investment can be high, PLCs reduce

long-term maintenance costs and increase productivity.

- Minimal Wiring Requirement

PLCs consolidate control systems, minimizing

the need for extensive wiring, which makes installation easier and keeps work

areas less cluttered.

PLC Applications

- 1. Industrial Process Control

Used in chemical, petrochemical,

and pharmaceutical industries to monitor and control complex

operations.

- 2. Factory Automation

PLCs help in running assembly lines,

packaging machines, and material handling in manufacturing

plants.

- 3.Food Processing

Helps with mixing, packaging, and

maintaining quality standards in food and beverage industries.

- 4. Water Treatment Management

PLCs regulate purification

process, check water quality, and handle distribution in treatment

plants.

- 5. HVAC Control

Manages heating, ventilation, and air

conditioning systems by regulating temperature, humidity, and air

quality.

The Future of PLCs

Understanding the basics of Programmable Logic Controllers (PLCs) is crucial for

mastering modern machine control, as they form the backbone of industrial automation.

A Programmable Logic Controller, or PLC, is an industrial computer that can be

programmed to control machinery and processes in various industries. With

components such as a CPU, input/output modules, and a programming device, PLCs

are versatile tools, integral to applications ranging from simple control tasks to complex

automation systems. For anyone new to industrial automation, understanding PLCs is

an essential first step.

PLCs remain evolving with technology. There are newer products in the form of

Programmable Automation Controllers (PACs), which combine the functionality of PLCs

with higher-level PC functionality. Even with these innovations, PLCs remain widely

popular for their affordability, simplicity, and effectiveness.

Cognidel is a leading industrial automation training institute renowned for its hands-on, industry-oriented programs, particularly in the field of Programmable Logic Controllers (PLCs), SCADA systems, and related automation technologies. With a strong focus on practical learning, Cognidel equips students and professionals with real-world skills through hands-on labs and industry-based projects. Recognized for its quality and commitment, it stands out as a top destination for PLC training in Bangalore, helping learners build a solid foundation and advance their careers in the automation sector.