In the present-day world of industrial automation, PLCs have almost completely replaced traditional relay systems. Today almost every industrial process has a process control computer whose function would be to ensure precision in the process of controlling different industrial processes. Manufacturing plants and energy sectors are only a few of the many applications of PLCs that exhibit improvements over relays systems.

A relay function as a switch that is used to open or close a circuit. Relay works based on the principle of electromagnetism, consisting of a coil that creates a magnetic field when current passes through it, enabling the switching mechanism. A relay can be either normally open (NO) or normally closed (NC) depending upon the input.

In the past, relays were commonly used in industrial control systems instead of PLCs (Programmable Logic Controllers). However, they had several drawbacks:

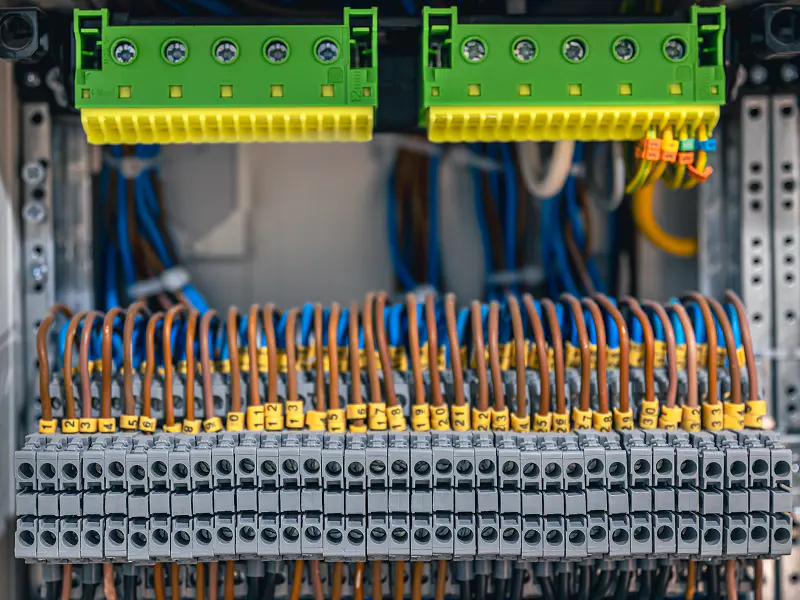

To address these challenges, PLCs were introduced. These programmable logic controllers possess a processor and a specific input/output section allowing them to perform various complex logical functions quickly. PLCs eliminated the need for complex wiring as with relay systems making it easier and faster to troubleshoot wiring faults. PLCs have a higher number of input output points compared to relay, enabling them to perform more complicated operations.

A PLC works by receiving inputs from field devices through its input module. Then, it passes the input to the processor for comparison with the pre-programmed logic. Based on this comparison, the processor generates an output signal according to the programmed logic. The output module sends signals to field devices.

Although computers are normally superior to PLCs in terms of computation and memory, they are not meant to be the best in terms of industrial control reliability. Whereas PLCs are specially designed to take care of all types of contingencies regarding power surges, spikes,or crashes, computers would be disrupted if any of these were to happen.

Cognidel is a premier industrial automation training provider that offers comprehensive courses in different automation technologies. With a focus on providing hands-on experience and practical knowledge, Cognidel has become a trusted name for those seeking PLC training in Bangalore. The courses are designed to equip students with essential skills to excel in the automation industry, combining theoretical knowledge with real-world applications. Partnering with industry experts, Cognidel offers training programs that are up-to-date with the latest technology evolution.

As one of the top institutes offering industrial automation courses in Bangalore, Cognidel provides specialized training in areas such as PLC, SCADA, DCS, and industrial robotics. The courses will prepare any aspiring automation or industrial professional to efficiently manage and operate complex industrial systems. Whether you want to learn a few skills or jump-start a new career in automation, Cognidel has the right training courses for you in this fast-evolving sector.